MUNICIPALITY

Why a Municipality Should Choose a Total Biosolid Management Solution

- Eliminates requirement for large capital investment in plant & equipment.

- Eliminates credit rating issues that may arise from borrowings to purchase expensive plant & equipment.

- Allows municipality to budget for fees and expenses charged by TBM service provider as part of the annual operating budget.

- Faster startup of biosolids management plan, because approvals of capital investment in plant & equipment and borrowings to purchase plant & equipment are eliminated.

- Eliminates requirement to hire and train personnel involved in biosolids management plan.

- Eliminates requirement to purchase consumables and spare parts inventory.

- Eliminates economic losses resulting from ownership of depreciable plant & equipment, as a result of wear & tear and obsolescence.

- Eliminates the day-to-day challenges, problems, and disappointments of having to manage personnel, maintenance of equipment, the operation of equipment, detailed biosolids management plan expenses, the handling, storing and transportation of biosolids, and the product quality of the resulting Class A Biosolids, all of which will be handled by the TBM service provider.

- Ensures that resulting Class A Biosolids will be handled, processed, stored and transported in a prudent manner and will be beneficially used in accordance with applicable state and federal regulations.

- Ensures that biosolids will be processed, handled, stored, transported and beneficially used in a manner that results in highest level of environmental benefits, including reduction of methane gas emissions, improvement of soil fertility, improvement of agricultural crop production, reduction of agricultural industry's use of commercially produced fertilizers, and environmental improvement of natural waterways.

- Results in substantial economic benefits by eliminating transportation and landfilling of wet biosolids.

- TBM Solution can be structured at a cost that is less than the municipality's total long-term cost of owning, operating, maintaining and managing the plant & equipment that it would be required to purchase for the purpose of implementing its biosolids management plan.

MANNCO PROJECTS

REGULATIONS

Biosolids Regulations

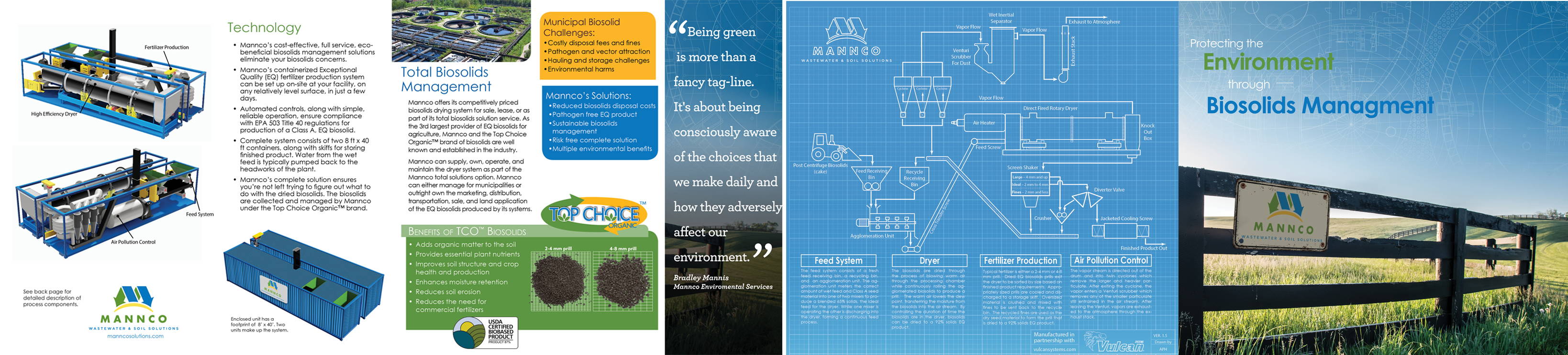

Mannco Wastewater Solutions, LLC is fully committed to environmental protection, high standards of operations and meeting and/or exceeding all regulatory requirements. Regulations that ensure the safe and responsible recycling of biosolids have been in effect since the 1970's. The Clean Water Act amendments of 1977 and 1987 require comprehensive controls on biosolids recycling. More directly, the EPA Part 503 Biosolids Rule establishes biosolids quality requirements and encourages recycling biosolids.

By following federal, state and local regulations, municipalities and companies such as Mannco can safely recycle biosolids for the benefit of farms, forests, and landscaping - all of which improves soil properties and helps the environment.

The use of biosolids as a soil amendment is beneficial to farmers, municipalities and communities across the nation. U.S. Environmental Protection Agency (USEPA) supports the recycling of biosolids as an environmentally safe method to reuse the plant available nutrients and organic matter. Organic matter is the most significant factor in giving the soil a spongy texture so it holds water and nutrients preventing them from running off and causing erosion.

Mannco is proud to be an active part of helping to create a more sustainable environment. Not only this, but also taking an active role in the education process for consumers and the general public too.

PRODUCT

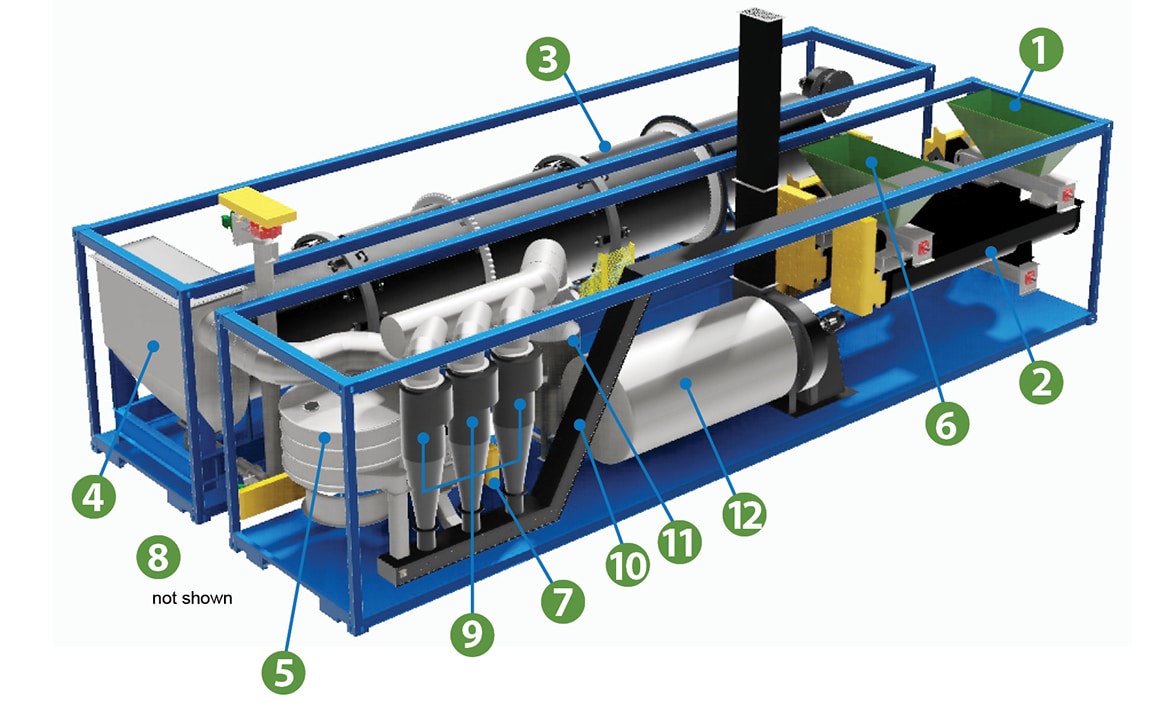

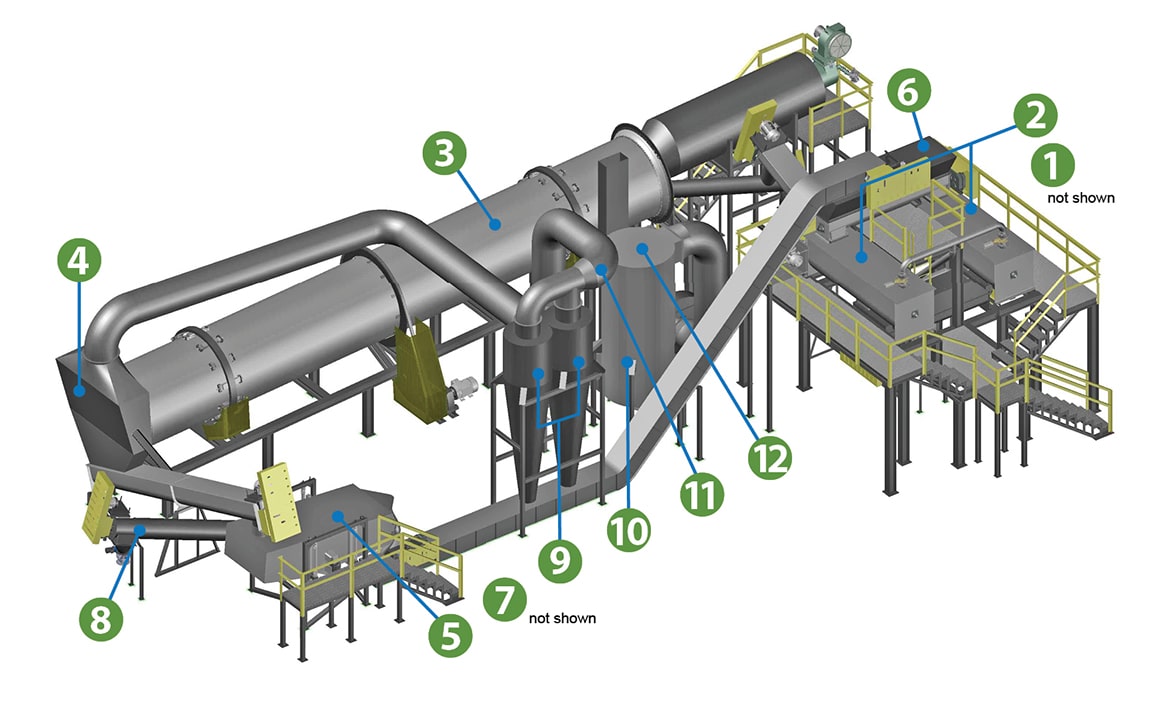

Mannco's Modular Class A Biosolids Dryer

TOP CHOICE ORGANIC®

The result is Top Choice Organic®

Top Choice Organic® is an exceptional quality granular organic biosolid fertilizer composed of greater than 80% natural organic matter, with a moisture content of less than 10% and a uniform granule size of 2 to 4 millimeters.